New Balance to release 3D-printed running shoe

New Balance had already announced plans to offer consumers the first performance running shoe with a full-length 3D-printed midsole. Those plans will go into action starting at 9 a.m. ET on Friday, April 15 in Boston.

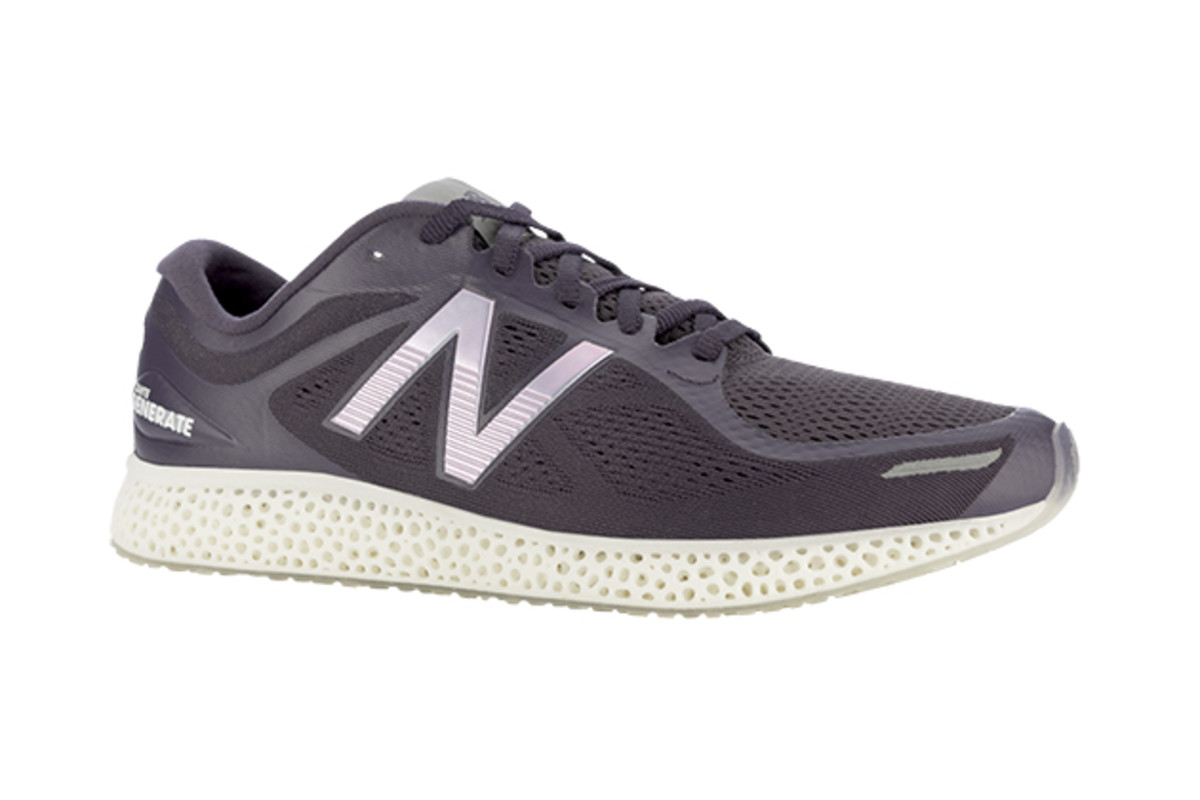

The Boston-based company will start with 44 pairs—New Balance was founded 44 years ago—of its Zante Generate shoe, on sale online and at its Boylston Street shop for $400. New Balance plans to expand its 3D printing in the future.

Tech Talk: Under Armour steps out with first 3D-printed training shoe

New Balance has used 3D printing to fine-tune high-end track spikes since 2013, later building cleat plates for soccer. But those products were not available to consumers. On Friday, the company will become the first to offer 3D-printed running shoes to consumers, following on the heels of Under Armour becoming the first to offer 3D-printed trainers in March.

An exclusive collaboration with 3D Systems allowed New Balance to create an elastomeric powder, DuraForm Flex TPU, to build a new style of midsole the company says offers “an optimal balance of flexibility, strength, weight and durability.” That elasticity is what allows 3D printing to move beyond the hard plates of spikes and cleats and into the flexible midsole of running shoes.

TheZante Generate midsole includes an intricate 3D-printed honeycomb structure offering hundreds of small, open cells for both cushioning and stability. A laser—as part of the selective laser sintering process—turns the powder into solid cross-sections layer by layer in New Balance’s Lawrence, Massachusetts, factory. The upper of the Zante Generate uses a bootie construction and engineered mesh.

Tim Newcomb covers sports aesthetics—stadiums to sneakers—and training for Sports Illustrated. Follow him on Twitter at @tdnewcomb.