Sole music: Inside Brooks Running's new HQ and research lab

SEATTLE -- The Burke-Gilman Trail, which runs for nearly 20 miles in and around Seattle, joins city streets at just one point, exactly where Brooks Running built its eco-friendly new headquarters and state-of-the-art research lab.

The move, in August, from suburban Bothell to Seattle’s Fremont district put Brooks at the center of Seattle’s running culture, allowing the 100-year-old company a literal connection to the city’s longest trail and space to open its first showcase retail store.

That centerpiece store takes up the ground floor of the targeted LEED Platinum five-story building. The retail space is designed to be adaptable, providing space for selling performance running merchandise, showing off the new heritage line of shoes to celebrate the company’s anniversary or hosting community events or presentations.

Yes, Brooks has retail, a third floor that houses marketing teams, a top floor for corporate offices—plus a cool cafeteria with a view across Lake Union of the Space Needle—and even a rooftop deck that hosts yoga. But the even-numbered floors provide the most pizzazz.

On the fourth floor you’ll find footwear and apparel, tucked closely together alongside a materials library, where operations personnel can whip together examples for designers and teams can collaborate on projects. But all that creativity doesn’t happen without the benefit of science, which is where Brooks’ new 4,432-square-foot research laboratory, dubbed NEXT Lab and housed on the building’s second floor, comes into play.

Why the Panthers' Thomas DeCoud owns hundreds of shoes

“We designed it for the future,” Brooks senior biomechanical engineer Eric Rohr tells Edge.

Within NEXT, expect to find machines testing products and technology testing athletes. Sometimes those two activities merge.

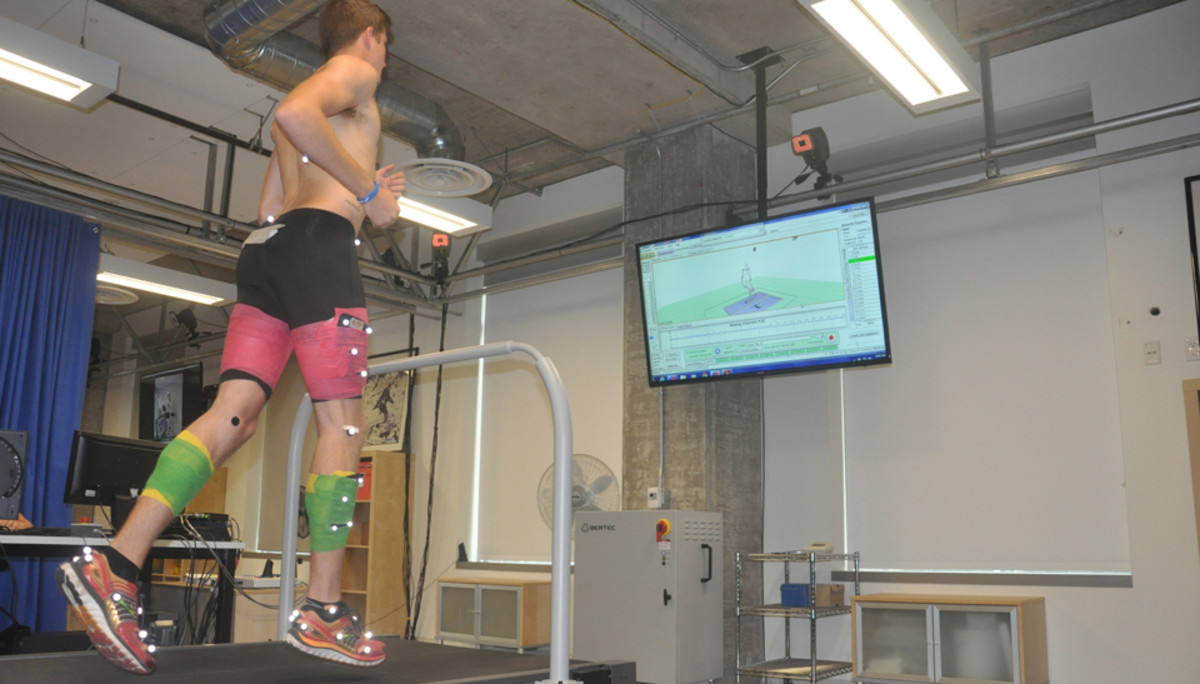

Two instrumental treadmills provide stats aplenty, with eight infrared cameras picking up data from sensors attached to the runner and to the athlete’s shoes. Everything from exact toe movements to changes in stride over the duration of a run is tracked in real time.

“We can understand how a runner moves and how force travels in the body, from the speed of the ankle to the toe-off,” Rohr says. “There are tons of parameters. It gives us a holistic perspective.”

Brooks also uses force plate technology to capture pinpoint data on how a foot—and shoe—moves when contacting the ground. The company’s researchers can also place different surfaces over the force plate, testing everything from trail shoes to track spikes. As Brooks continues to expand, says Pete Humphrey, vice president of research and development, the lab will add more force plates.

The technology expands from there with 3-D cameras allowing the staff to understand body motion from any angle, high-speed cameras to slow that movement down and thermal cameras to explore the ability of apparel to regulate temperatures.

“By keeping the room open, we can adapt and understand different types of movements,” Rohr says.

With a third data-collection bay still open, the research team, which also includes biomechanist Stacy Steffen, plans to add an environmental chamber.

A 3-D printer and the ability to manipulate materials on site speeds up the testing process while researchers explore new ideas. With the mechanical and biomechanical areas joined together, the team’s “insight area,” a place to brainstorm ideas, allows art to also infuse the space. “We integrate the whole system,” Rohr says.

The system begins with an understanding of the runner, all grounded in a fundamental understanding of biomechanics. By combining the needs of runners with what Brooks knows about biomechanics, the research team works with designers on the fourth floor to create new products—or adaptions to what they already have—that can offer a “better, faster, safer run.”

For example, instead of producing shoes intended to correct a runner’s form, Brooks has created Stride Signature, a focus on identifying the highly individual characteristic of each runner’s stride. The Brooks researchers want to work with the natural motion and paths of a runner’s joints to find each person’s “preferred path” of running, keeping them comfortable while on the road or trail.

Designing the ultimate pro athlete recovery center — in the air

Using data gleaned in the NEXT Lab, Brooks designs with the exact type of foam, rubber and pattern for a person’s individual “pathway.” Pressure mapping determines where to place harder midsole foam that provides 25 percent more cushioning, while biomechanical testing helps decide where to locate “guide rails” that offer “technology that engages the runner only when they need it.” In the end, every small iteration of the Brooks Running line comes through the research carried out in the lab.

“We build product for experiences,” Rohr says. Clearly, Brooks is determined to find the NEXT best thing.

Tim Newcomb covers stadiums, design and gear for Sports Illustrated. Follow him on Twitter at @tdnewcomb.